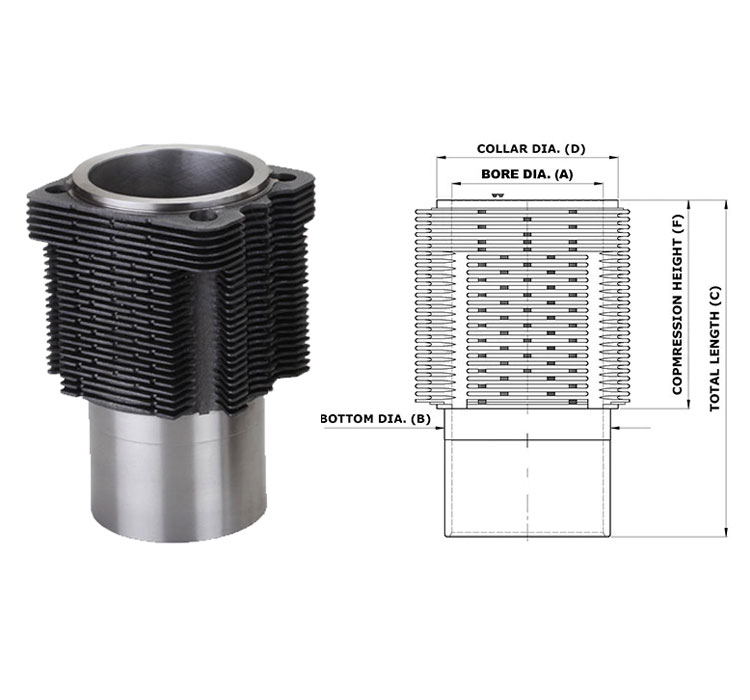

CYLINDER LINER

CYLINDER VALVE

AIR COOLED BLOCKS

We offer Cylinder Liners, Sleeves and Air Cooled Blocks according to OE specifications, upgraded specifications or as per client's requirements to suite their market needs. The extensive design and material expertise of diesel power Engineering guarantees high-performance and cost-optimized products which withstand the toughest operating conditions

Diesel power manufactures Cylinder Liners in gray cast iron using centrifugal casting. Special chemical compositions are also used to ensure corrosion resistance properties and enhanced lubrication. Centrifugal Casting Process is known to be the best method for manufacturing Cylinder Liners. In centrifugal casting, a permanent mould is rotated continuously about its axis at high speeds as the molten metal is poured. The centrifugal force causes the metal to distribute itself evenly around the die. The resulting casting is a fine-grained casting with a very fine-grained outer diameter, owing to chilling against the mould surface. Impurities and inclusions float to the surface of the inside diameter, which can be machined away.

Air Cooled Cylinder Liners are made from special “Shell Moulding Process” having wear resisting close grained iron casting to ensure long life and efficient cooling.

Production Capacity

1.1million pieces per annum

Size Range (In mm)

Bore Diameter75.00 to 170

Total Length150.00 to 330

Finishes

Semi-finished & Fully-finished

Micro Structure

- Predominant distribution A, permitted B and D Size 4~6

- Pearlite (Max 2% ferrite)

- Dispersed network of steadite

- Carbides Max. 1%

Hardness (BHN)

240 to 260

Tensile

210 to 275 n/mm2

Chemical Composition

| Name | Minimum | Maximum |

|---|---|---|

| Chromium | 0.25 | 0.50 |

| Carbon | 3.00 | 3.50 |

| Silicon | 2.00 | 2.50 |

| Manganese | 0.50 | 0.80 |

| Phosphorus | 0.3 | 0.50 |

| Sulphur | - | Max. 0.05 |

| * custom | - | - |

Other than above, we can cast material compositions using Chromium, Molybdenum, Nickel, Copper, Boron or as per customer specifications meeting to international standards.